|

|

|

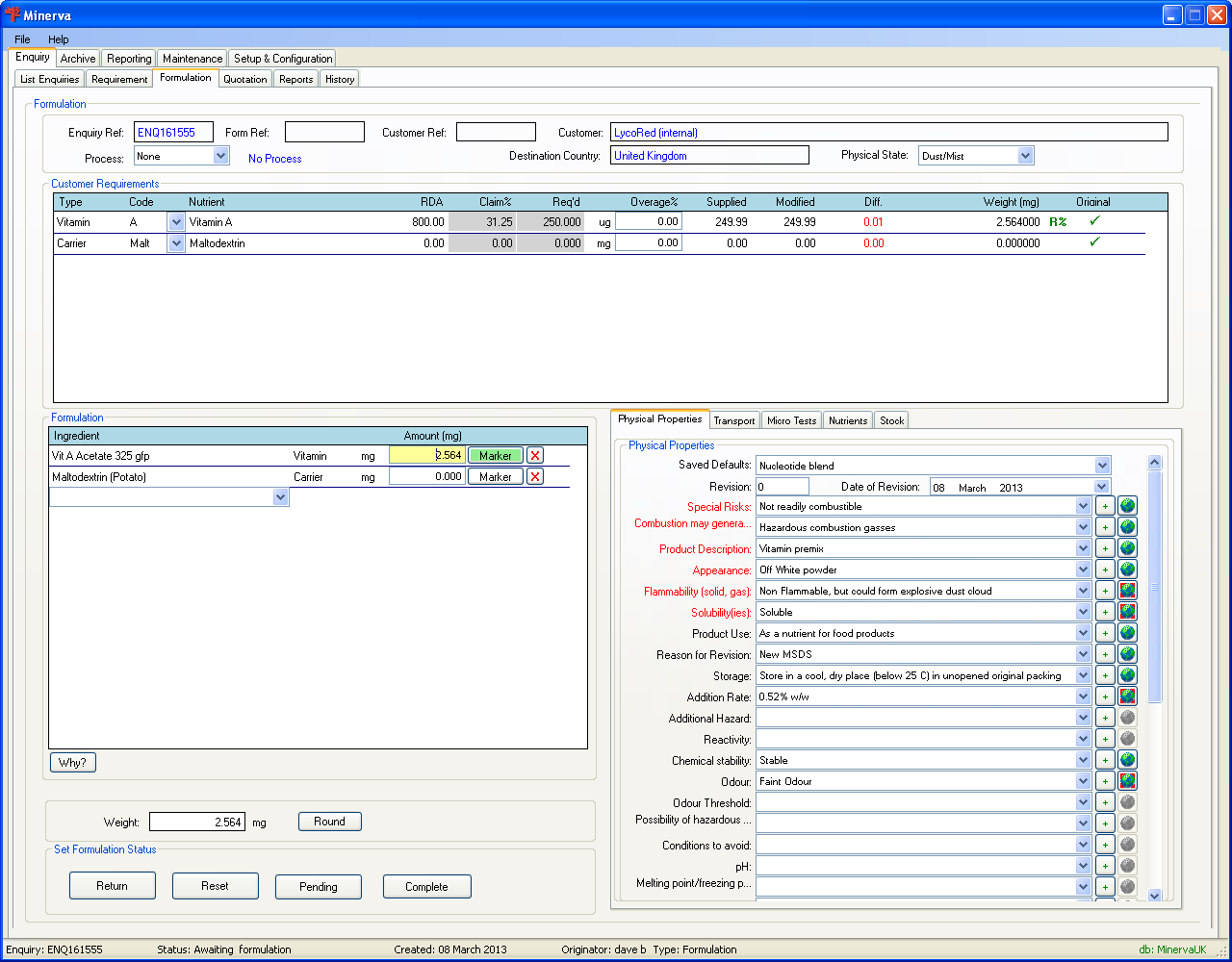

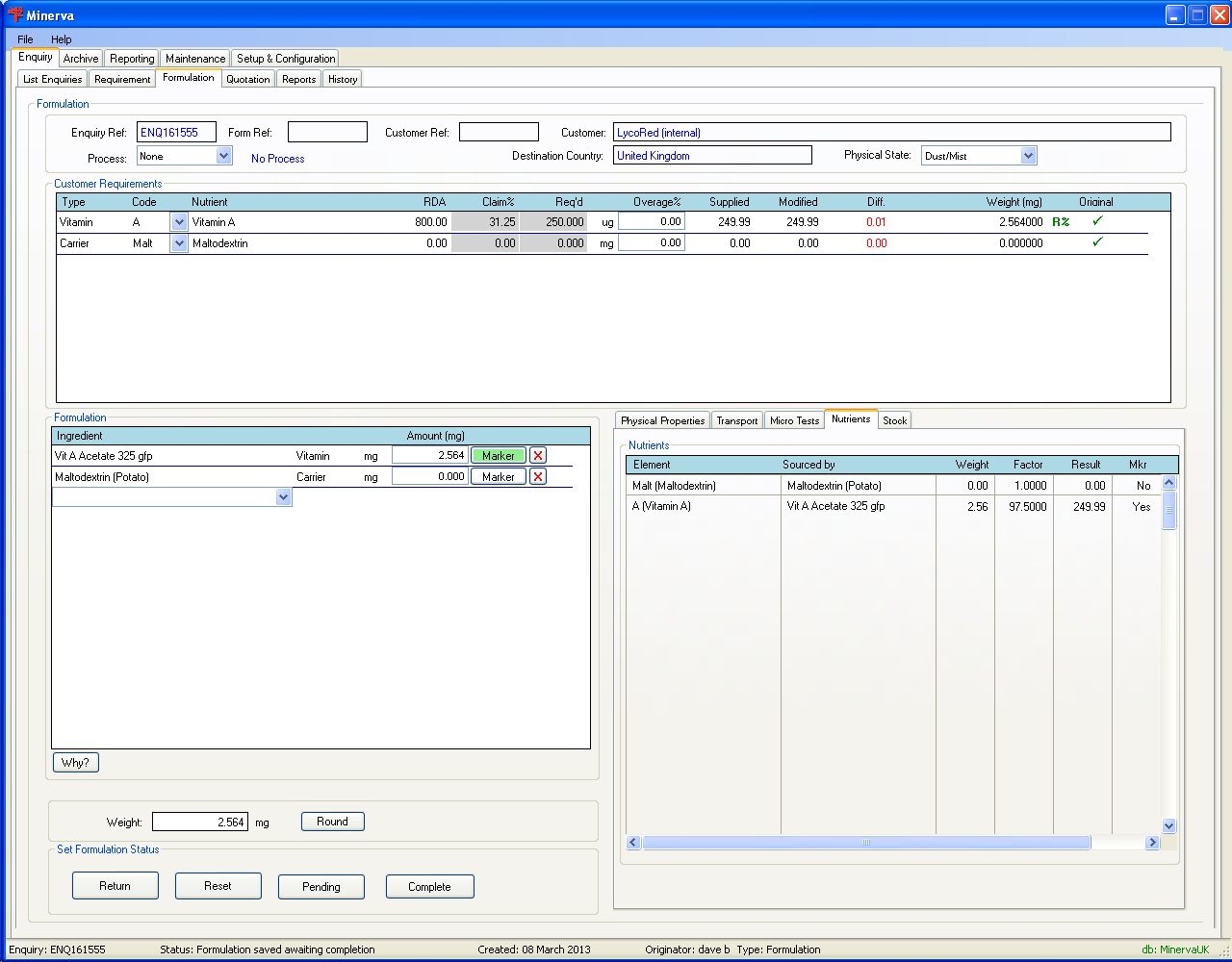

This screen allows you to select the ingredients to fulfil the customer's requirement

| Field | Description |

| Enquiry Ref | This shows the enquiry reference code which is generated for every enquiry. |

| Form Ref | This is the formulation reference which is generated when you get to this stage of the enquiry. |

| Customer Ref | This is the reference that the customer has supplied for their enquiry. |

| Customer | The customer name |

| Process | This allows you to select a process which will add a percentage to substances that could lose some of their strength through heating the formulation. |

| Destination Country | The country where the customer is based. |

| Physical State | Under the GHS/CLP Acute Toxic classifications the inhalation category has been sub-divided into Dust/Mist, Gases and Vapour. These sub-categories each have different break-point values. |

| Field | Description |

| Type | The component type. |

| Code | The component code. |

| On a formulation type of enquiry you will be required to select the substances to fulfil the component. The dropdown list will only show the substances that contain the components that match or is better that the required shelf life and match any preferences on the requirements tab. Select the substance that you require, the substance will be shown in the Formulation area with the calculated quantity required to fullfill the components requirement. | |

| Nutrient | The component name. |

| RDA | The RDA value for the component. |

| Claim% | The claimed RDA percentage for the required amount. |

| Req’d | The amount required using the weight type shown on the right. |

| Overage% | This is the percentage that will be added if a process is selected in the formulation area. |

| Supplied | The amount of the component supplied. This value will be increased if you have selected a process which includes this component. |

| Modified | This field shows the amount of the component without any overage percentage being included. This value depends on the strength of the component within the substance. |

| Diff. | This is the difference between the required amount and the modified amount. When a substance selected in the formulation area has two or more components any extra components will be listed but will show “”. When you are entering an enquiry with a type ‘Formulation’ then these components will not be shown on the documentation. |

| Weight (mg) | This is the amount of the component, in mg, that will be required to fulfil the component’s requirement. You could see an here in green, amber or red, this is used as a warning to you that the weight% is different to the Req’d weight. Green means the amount is within the target range, amber is outside the optimal tolerance range and red the amount is outside the tolerance range. |

| Original | This will show a tick if the component was selected on the enquiry requirements tab. |

This is the area where the substances to fulfil the formulation are shown with the amount required.

When you are creating a ‘Recipe’ type of formulation these substances will be shown when you arrive on the tab and the customer requirement area will be populated using these substances to get the component information.

When you have completed the formulation then you must enter the details on the Physical Properties tab, the properties in are mandatory fields. These properties are used to complete the MSDS and other documentation, when you do not know the information leave the field empty then on the documentation the system automatically enters "No Data" for you, this is because under EU Regulations all properties must be shown on the MSDS.

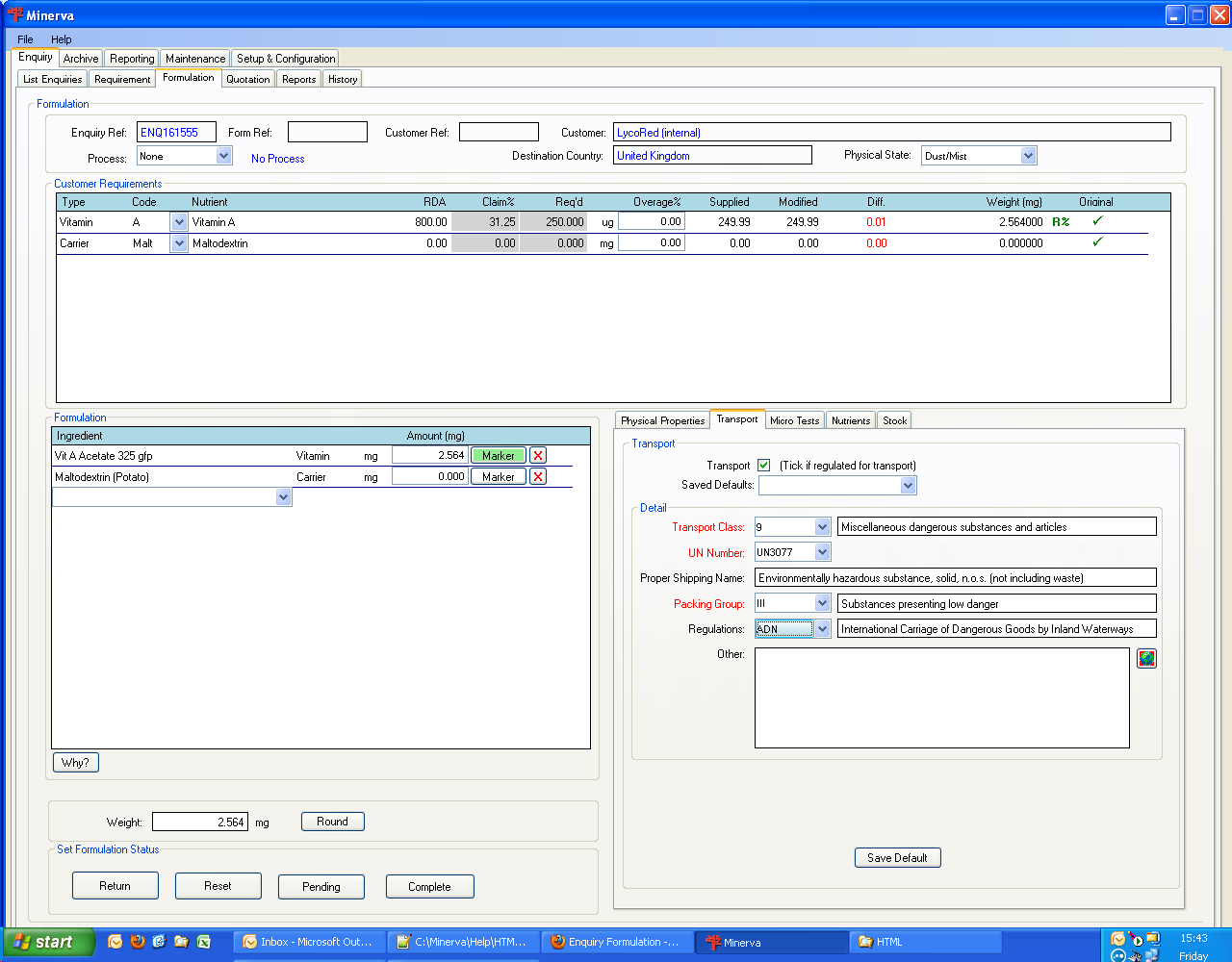

To enter transport information click the tab to enter any United Nations transport codes for the mixture. Note: the North America area, these are also known as DOT numbers which are identical to the UN codes, except that some substances without a UN number may have a NA number. These additional NA numbers use the range NA8000 - NA9999.

Tick the "Transport" option to enable the fields, then when you have already saved transport values click the "Saved Defaults" drop-down list and select the required details.

Select the Transport Class

Select the UN Number this will give the Proper Shipping Name

Select the

Select the applying

You can now enter any other notes about the transport code that will appear on the MSDS in the transport section, such as tunnel code and EMS code.

You can save this transport information so that you can use it on multiple formulations. Click and you will then be asked for a name for the details, we recommend that you use the transport code as the name, with the packing group.

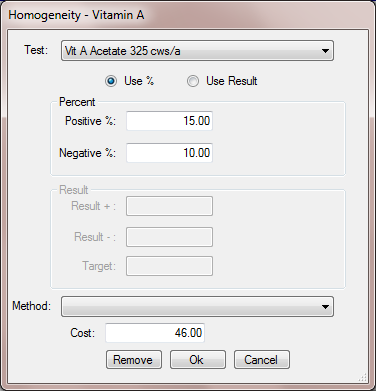

When you need to test that the ingredient is homogenised throughout the mixture click the button beside the ingredient which will then show the following screen.

| Field | Description |

| Test | Select the test to use. Only active tests for the nutrient are shown. |

| Buttons | |

| Remove the test from the nutrient/component. | |

| This button saves all changes made to the test and closes the window. | |

| This button cancels all changes made to the test and closes the window. | |

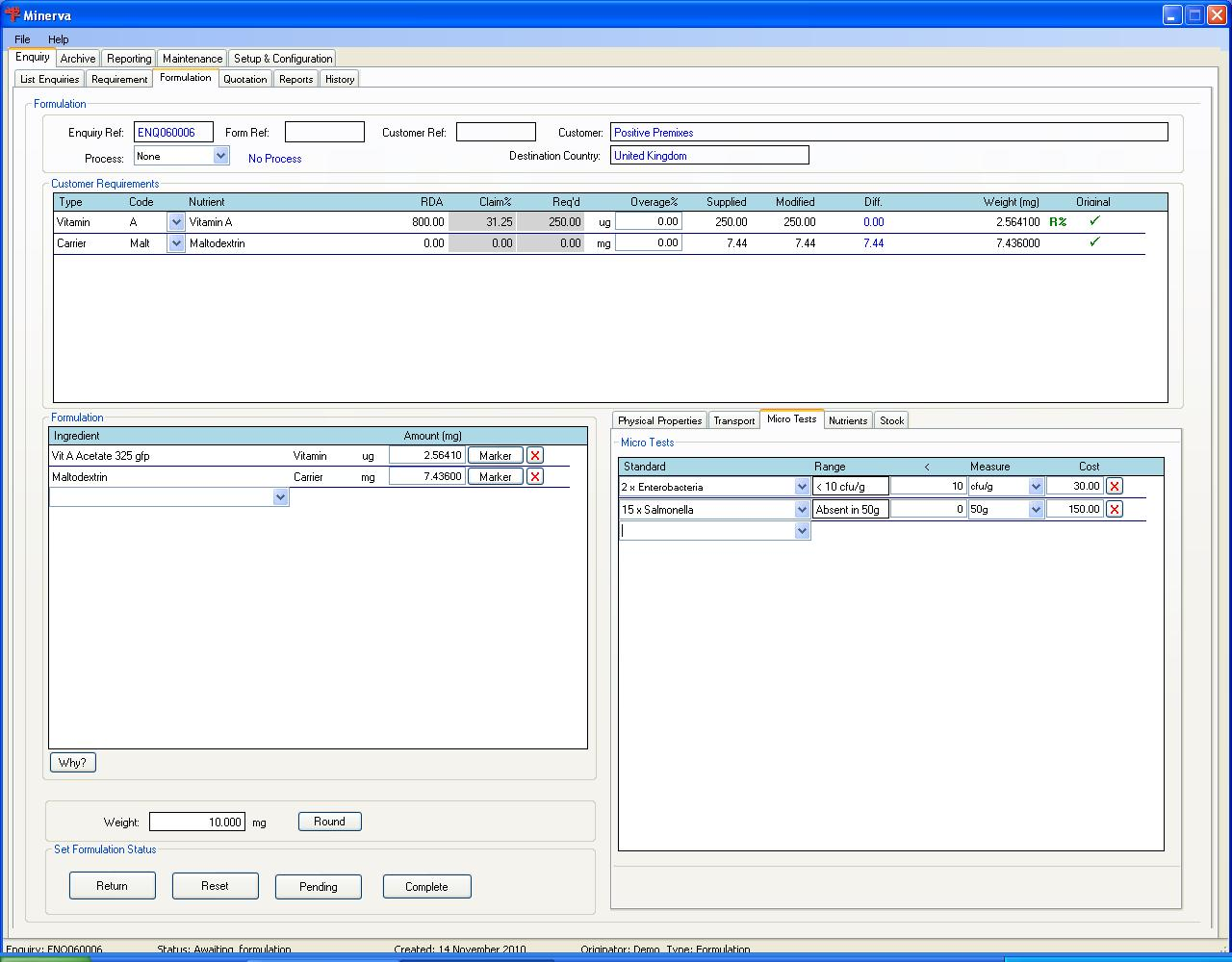

If you need any Micro tests carried out on the formulation click the tab and select any tests required, you are able to change the price for the test for this formulation.

The Nutrients tab shows you the components and which substances are used to fulfil the requirement. Where a substance has two components and both components were requested then the substance will be shown against both components.

The Stock tab will be blank unless Minerva has been connected to a external stock system.

When you have entered all of the information you can click the button to save and move to the Quotation screen, if you just want to save and exit the formulation then click the button.